| ID |

Date |

Author |

Location |

Severity |

Subject |

|

226

|

12 May 2017, 09:23 |

NEREA JARDON | XTD9 | Information | Motion loop | Dear all,

Due to local test needed in Rack 1.18 for the Motion loop, the loop will be interrupted only in Rack 1.18 XTD9 from now till the people in the Tunnel finish the tests. It will not affect any other part of the Motion loop.

Thank you. |

|

236

|

16 May 2017, 13:50 |

NEREA JARDON | XTD9 | Information | Motion loop | Dear all,

Due to local test needed in Rack 1.18 for the Motion loop, it will be interrupted only in Rack 1.18 XTD9 from now till tests finish. It will not affect any other part of the Motion loop.

Thank you. |

|

291

|

15 Jun 2017, 12:18 |

Gerd Wellenreuther | XTD9 | Information | Access to tunnels updated | XTD9 will be open until Friday this week 13:30. Check https://docs.xfel.eu/share/page/site/PSC/wiki-page?title=Tunnel_access_schedules |

|

295

|

19 Jun 2017, 16:55 |

Gerd Wellenreuther | XTD9 | Information | Access to tunnels updated | Tunnel access schedule has been updated, access for XTD9 on Wednesday from 7-14:00 is now for granted.

https://docs.xfel.eu/share/page/site/PSC/wiki-page?title=Tunnel_access_schedules |

|

311

|

04 Jul 2017, 09:41 |

NEREA JARDON | XTD9 | Information | Motion loop | Dear all,

Today we are planning to integrate part of Hirex motors into the Motion loop of SASE1. Therefore, the loop will be break, so you will loose communication with whole XTD9 Motion part. I will back again to you when we are done,

Thank you |

|

317

|

06 Jul 2017, 08:51 |

Gerd Wellenreuther | XTD9 | Information | Tunnel access schedule updated | Dear all,

access to XTD9 has been extended until the Friday the 14.7. 14:00. Tunnel access schedule has been updated:

TAS

Cheers, Gerd |

|

329

|

13 Jul 2017, 10:27 |

NEREA JARDON | XTD9 | Information | Vacuum Loop in XTD9 | Dear all,

One power supply needs to be changed in SASE1 XTD9 rack 1.12 tomorrow and it's related to the Vacuum loop. Denis Finze will do this change tomorrow morning, but we have to make sure before that we have all the equipments after this rack 1.12 in safe state (most concerning part, XGM in XTD9). Please, could you make sure that everything it's ok tomorrow at 10am? However I will send an email now to the involved people.

Thank you and best regards, |

|

334

|

14 Jul 2017, 12:44 |

Martin Dommach | XTD9 | Problem | Fast Valves in XTD9 | Dear all,

the fast valves in XTD9 were causing some trouble. From time to time they collect some electrical noise what triggers the valve. The pressure reading on the valve controller then shows oscillations of up to 10^-5 mbar, while the pressure around the fast valve gauges in the beamline is in the 10^-9 mbar range.

To operate the beamline in the meantime I have opened and disabled both fast valves.

This needs further investigation on the service day next wednesday.

Best regards,

Martin |

|

346

|

26 Jul 2017, 18:04 |

Martin Dommach | XTD9 | Information | Fast valves in XTD9 | Dear all,

the problem with the fast valves XTD9 tripping randomly is still not fully understood but we exchanged the controllers for both valves and they now seem to be stable. The valves are set back to active mode again with 1*10^-6 mbar trigger level while vacuum pressure at the sensors is around 1*10^-8 mbar.

In case one of the valves closes again in the next time you can do the following:

1. check the ion pump pressure in the beamline to make sure that it’s not a real event (they should be in 10^-8 mbar range or better)

2. If it’s not a real vacuum inrush you can open the valve by pressing “Open" button followed by the “Reset” button (SPB: Karabo scene SA1_XTD2_VAC/V11030F or for FXE: SA1_XTD2_VAC/V12030F )

3. Open the adjacent gate valves which were triggered by the vacuum interlock and continue with beam operation

4. Please inform the vacuum group (vacuum@xfel.eu)

If opening the valve again does not help because it trips to often, the fast valve can be disabled:

1. Open the valve by pressing “Open” button

2. When the valve is open again, switch off the high voltage of both sensors

3. Please inform the vacuum group (vacuum@xfel.eu)

Best regards,

Martin |

|

3

|

03 Nov 2016, 12:58 |

Alessandro Silenzi | XTD2 | Information | Current PLC-Karabo Conflict | Tobias Freyermuth and me worked on the system and as of last night, we found two new issues between Karabo and the PLC interlock:

- one is a Karabo issue from the Interlock PLC interaction, the Karabo device waits for a PLC response that does not come when the PLC is interlocked (i.e. Karabo wants to open a valve but the PLC correctly refuses and ignores the command)

- one is a PLC issue, the interlock is not triggered in all cases after testing (e.g. a ion pump out of set point does not closes a gate valve closure as specified).

The first one was reproduced with the BeckhoffSim simulation. It can therefore be fixed by CAS without dependencies from AE (except for the next integration test). |

|

4

|

03 Nov 2016, 17:00 |

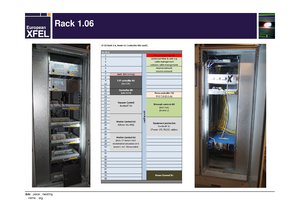

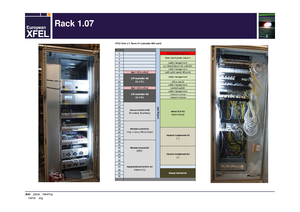

Sabine Cunis | XTD2 | Information | overview of required racks | just for reference ... here are pictures and schematics of the racks which are involved in the current commissioning. |

| Attachment 1: VCCT_Rack_1p06_b.jpg

|

|

| Attachment 2: VCCT_Rack_1p07_b.jpg

|

|

|

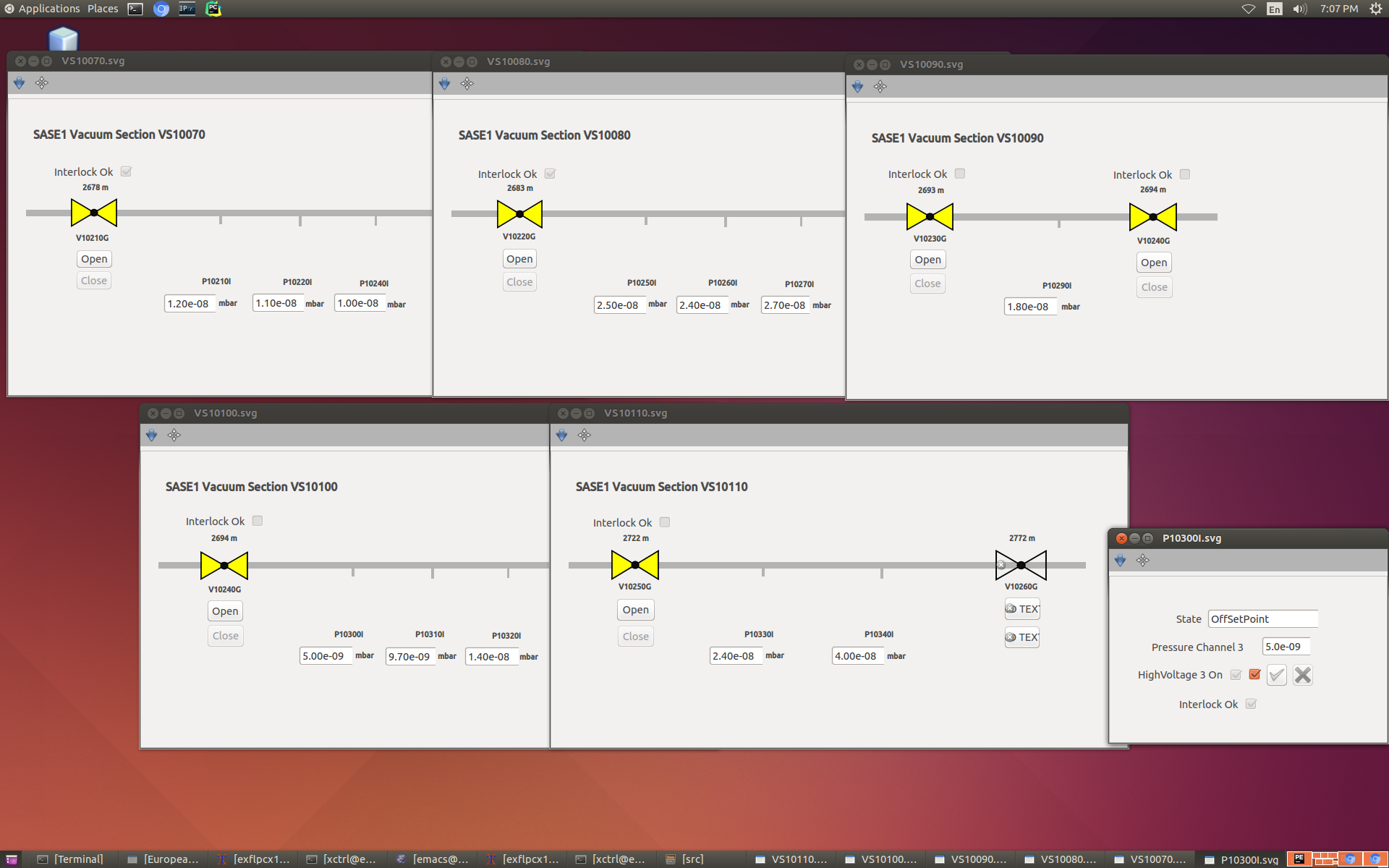

8

|

07 Nov 2016, 19:15 |

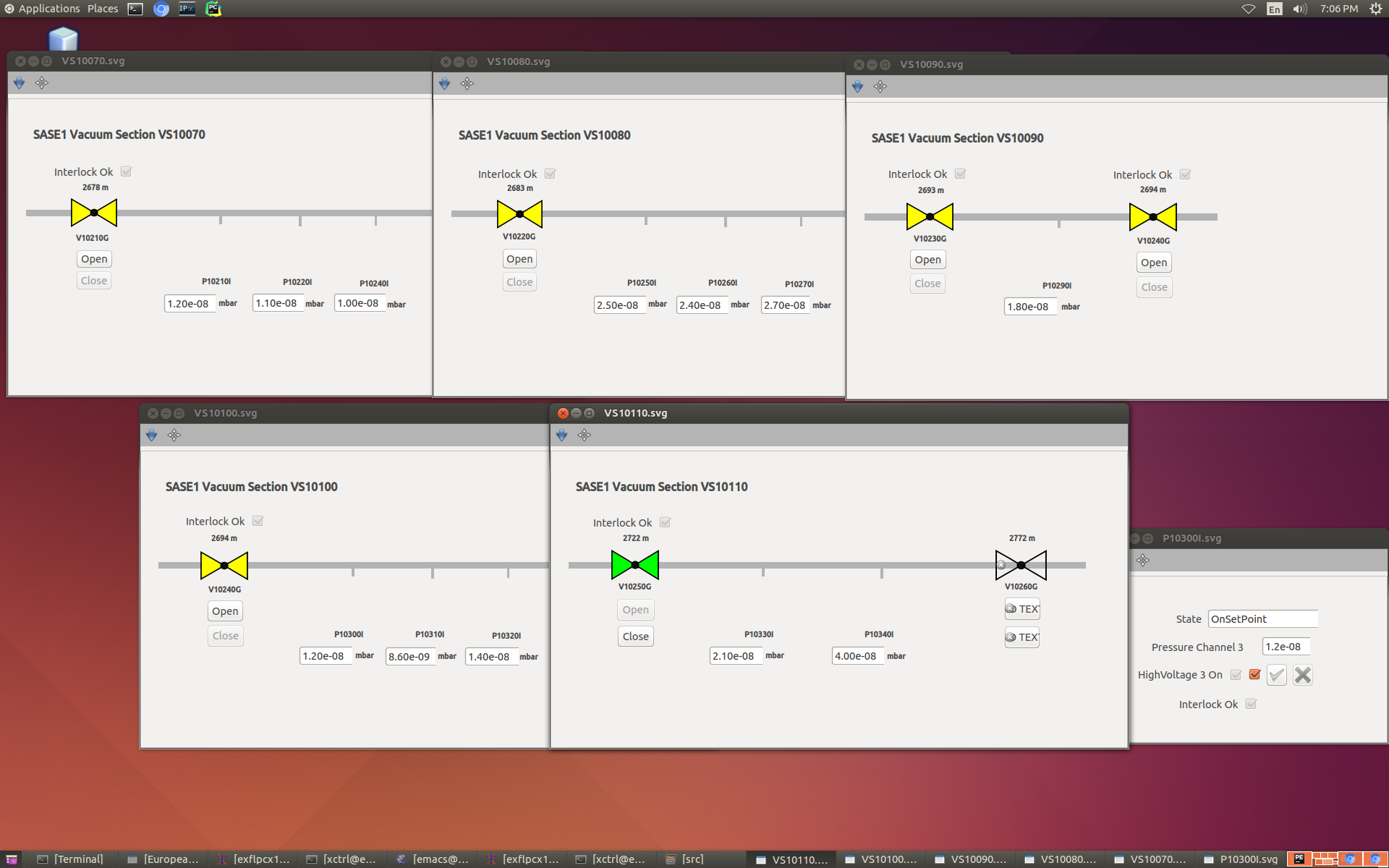

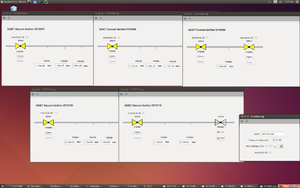

Alessandro Silenzi | XTD2 | Information | Karabo Installation back to normal | Karabo to PLC communication has been tested successfully in the SA1 Vacuum installation.

in attachment:

OK.png -> Initial Status, all OK

interlocked.png -> pump P10300I is turned off -> Setpoint -> off -> Valve automatically close and set "Interlock OK" to false

afteron.png -> pump P10300I is turned on again but-> Setpoint -> off -> Valve automatically close and set "Interlock OK" to false

backToNormal.png -> Like initial status but valves stay closed

|

| Attachment 1: OK.png

|

|

| Attachment 2: interlocked.png

|

|

| Attachment 3: backToNormal.png

|

|

| Attachment 4: afteron.png

|

|

|

13

|

02 Dec 2016, 11:43 |

Sabine Cunis | XTD2 | Information | new components list | please find the new (extended) components list under the old link given in the minutes http://tinyurl.com/zn7otsa ,

and check whether all components are included and charakterized by the correct data.

|

|

21

|

09 Jan 2017, 10:47 |

Sabine Cunis | XTD2 | Information | VCTF-list updated | The VCTF-components-list has been updated. Labels on components, as far as visible, are in accordance with names in list.

... please, check for consistency, when naming and labeling XGM components! |

|

22

|

24 Jan 2017, 08:17 |

Tobias Haas | XTD2 | Information | STATUS UPDATE: XTD2 Differential Pumping Modules running under interlock control | Post on behalf of Raul Villanueva:

As we just finished the exhaustive testing and final adjustments of local

test and the interlock program for each of the turbopumps at each

Differential Pumping Sections in XTD2 Tunnel, we are happy to announce

that the system has been released and is up and running smoothly and under

control. That means that the isolation gate valves in front of each

turbopump is open and therefore the latter is pumping already the beamline

as expected during the upcoming operation phase of the facility. That also

means that WP74, after having already received the wiring documentation

from the Vacuum Group can proceed with the same protocol to keep the whole

gas section in XTD2 in a consistent fail-safe status.

With this positive news, we wish you to have a nice evening,

Regards,

Raúl, Tobias and Nerea,

|

|

26

|

26 Jan 2017, 13:10 |

Tobias Freyermuth | XTD2 | Information | Modification of the vacuum PLC loop | |

The PLC program was modified and downloaded to the PLC, due to allow work on the XGM crate in rack 1.3.

The PLC vacuum loop includes now all vacuum crates in the racks from rack 1.1 to rack 1.7 except rack 1.3 (XGM)

|

|

27

|

26 Jan 2017, 17:02 |

Tobias Haas | XTD2 | Problem | XGM at XTD2 / issue with in-vacuum-resistor | Post on behalf of Jan Grünert:

during HV-tests on the installed XGMs, our DESY colleagues from Kai Tiedtkes team have found an issue with one of the electrodes / resistors inside one XGM vacuum chamber at XTD2.

Roughly, we know the following:

1) If not repaired, we would lose at least the capability of monitoring shot-to-shot horizontal beam position at this XGM location. This is a lower-priority info.

2) However, it’s not yet fully tested if other functionalities could be affected. In case the absolute calibrated intensity info is affected, then clearly we would have to repair.

3) Since the cause of the resistor-irregularity is not understood, there is a risk to damage the other (operational) remaining resistors in the other chambers of the same XGM.

It is not yet fully clear

a) what is the cause for the irregular behavior (it concerns a resistor inside vacuum which dramatically changed its resistance, which apparently possibly might happen even during a correct dry-nitrogen venting),

b) the entire consequences for operation with this XGM

c) the effort/details of a potential repair (could include up to removing one of the four chambers off the girder out of the tunnel into a lab, certainly needs re-survey)

d) if another XGM chamber is affected (so far tested 2 of 6).

The DESY colleagues are running various tests with us on the XGMs, also extending to all the other XGMs, to get answers to the above questions in order to allow a decision on “repair/not repair”.

Since this concerns the internals of the high-prio XGM in XTD2, we could ask Kai Tiedtke to give us his brief 10min report and recommendation in the tomorrow SASE1Readiness Meeting. Should we request his presence / will you add him to the agenda ?

Best regards,

Jan

________________________________________

Dr. Jan Grünert

Group Leader X-ray Photon Diagnostics (WP74)

European XFEL GmbH

Holzkoppel

|

|

29

|

27 Jan 2017, 10:22 |

Thomas Tschentscher | XTD2 | Information | Component table update | |

| Attachment 1: Components-XTD2-9.xlsx

|

|

30

|

01 Feb 2017, 17:26 |

Jan Grünert | XTD2 | Information | Status of several XTD2 wiring tasks - on behalf of Bernard Baranasic | Dear all,

today I connected XGM Gas Supply to Beckhoff terminals in WP73 Vacuum crate in Rack 1.3.

On Gas Panel, HUBA gauge is still not replaced, so it is not connected, I talked to Florian yesterday and give him an idea how we can connect this gauge and other signals for Gebäudeleittechnik (trough wago terminals).

Next step for this crate should be connection to all pump controllers and other vacuum equipment, after this crate should be connected to the tunnel vacuum loop. I assume that Torben and Marc can do this together with AE and Vacuum group, so I didn't take any actions...

Additionally in this crate we should connect Inhibit signal from HV iseg crate, for this we need to add:

Proposal from NC:

"I did not test it, to 'create' a TTL we can use either

es9505+es2624 or es9505+es2124

the only difference is that the ES2124 is short-circuit proof, the ES2624 is not, that means that in this case a Flink fuse ~0.3A-0.5A should be inserted."

- WP74 don't have these terminal here and if we order now it will take some time (I am not sure what to do because we don't have proven connection).

In Rack 1.7 I connected Inhibit connection to WP73 vacuum crate (terminals EL9505 & EL2624), but cable from MPOD crate to Beckhoff crate is still not there. Torben said that he has connectors so I believe he can connect according to electrical drawings (these pages are added to XTD2 MCP drawings on Alfresco)

In Rack 1.5 I tested FEL imager EPS switch and find out that Beckhoff terminal DI (ES1008) is not working (24V is on input, but there is no light on LED, all channels are the same).

EPS switch is removed From FEL imager, and I will reconnect it to Normal Open connection.

Best Regards,

___________________________________________

Bernard Baranasic |

|

36

|

02 Feb 2017, 18:29 |

Bernard Baranasic | XTD2 | Information | WP74 components in XTD2 - electrical connections | Status of WP74 components testing and wiring this week:

On Monday we tested SR Imager and K-Mono:

- issue with motor connect pinouts was discovered and I wanted to correct pinout today, but K-Mono and SR imager motor connectors are Lemo with soldering pins, which make pin changing more difficult than crimp version...

- this is still not done (we can exchange all connectors to crimp version or temporary change pins on crate side).

This week done:

- connected SR imager EPS switch (on the imager - not yet in the crate)

- On XGM Gas Panel is installed new HUBA gauge, and I connected it to the crate (now everything from Gas Panel is connected to Beckhoff terminals in WP73_VAC crate - Rack 1.3).

- FEL imager - EPS switch is connected properly, but Digital Input terminal in WP73 EPS crate - Rack 1.5 is defect (doesn't work at all).

- I placed cable for EPS switches of MCP detector, but not placed in the Rack (Rack needs to be opened - Roxtec feedthrough is closed)

To be done:

- K-Mono - switch pins 1 and 2 on Motor connectors (Y-1, Y2 and X).

- SR imager - switch pins 1 and 2, and switch pins 7 and 8 on all Motor connectors.

- SR imager - EPS switch connect from WP74 crate to WP73_EPS crate (one cable inside crate).

- XGM vacuum to HV crate interlock (inhibit) is still not connected (I am waiting for Beckhoff terminal, but this connection was not tested yet).

- MCP detector - EPS switch cable needs to be laid inside Rack 1.7 (Rack needs to be opened - Roxtec feedthrough is closed).

- MCP detector - vacuum to HV crate interlock (inhibit) needs to be connected - Beckhoff crate is prepared - missing cable from MPOD to Beckhoff terminals. |

|