ID |

Date |

Author |

Group |

Subject |

|

29

|

13 Feb 2023, 07:17 |

Tokushi Sato | SPB | Shift summary |

X-ray delivery

- 9.3 keV, 1-85 pulses, 1 mJ, stable delivery

Optical laser delivery

- 800 nm, 1-226 pulses, stable delivery

- ns laser for illumination

Achievements/Observations

- Successfull arrival time slope setting

- Pump-probe data collection at IRU with corrected time slope

Issues

|

|

28

|

12 Feb 2023, 06:53 |

Tokushi Sato | SPB | Shift summary |

X-ray delivery

- 9.3 keV, 1-85 pulses, 1 mJ, stable delivery

Optical laser delivery

- 800 nm, 1-226 pulses, stable delivery

- ns laser for illumination

Achievements/Observations

- Successfull arrival time slope setting

- Pump-probe data collection at IRU with corrected time slope

|

|

27

|

12 Feb 2023, 01:56 |

Jörg Hallmann | | Shift summary Feb 11th |

intense data taking on various samples

2 main issues:

- data collection using the optimize macro is too fast for the system and calibration and the data transfer from SDD to HDD is slower than collecting new data

- FSSS axis scannerY gives frequent errors since this night which is stopping the macro - check by morning shift & DOC is required |

|

26

|

11 Feb 2023, 13:55 |

Andreas Galler | PRC | Status |

Gun Modulator Problems

Gun Trip at 11:23 and since then the Modulator trips after each restart.

Accelerator Shift Crews and On Call personnel working on fixing the issue. |

|

25

|

11 Feb 2023, 07:06 |

Jayanath Koliyadu | SPB | Shift end |

X-ray delivery

- 9.3 keV, 1-85 pulses, 1 mJ, stable delivery

Optical laser delivery

- 800 nm, 1-226 pulses, stable delivery

- ns laser for illumination

Achievements/Observations

- Successfull arrival time slope tests

- GOTTHARD II data collection

- Pump-probe data collection at IRU with arrival time slope

Issues

|

|

24

|

11 Feb 2023, 01:09 |

Jörg Hallmann | MID | Shift summary |

sucessfull data taking for user samples

beam loss for ~15 min and a small issue with scannerX of the FSSS (could be fixed without support) but otherwise smooth operation

contact with ITDM since the data collection speed could be too high for the transfer speed from SDD to HDD - should be kept under investigation....

|

|

23

|

10 Feb 2023, 08:17 |

Jayanath Koliyadu | SPB | Shift end |

|

X-ray delivery

- 9.3 keV, 1-85 pulses, 1 mJ, stable delivery

Optical laser delivery

- 800 nm, 1-300 pulses, stable delivery

Achievements/Observations

- Optimization of ns laser for illumiation and PP laser polarization

- Optimization of X-ray beam alignment and scattering background on AGIPD

- Timing at IRU and PAM

- GOTTHARD II timing scan and data collection

- Pump-probe data collection at IRU

Issues

|

|

22

|

09 Feb 2023, 07:14 |

Jayanath Koliyadu | SPB | Shift end |

X-ray delivery

- 9.3 keV, 1-85 pulses, 1.3 mJ, stable delivery

Optical laser delivery

- 800 nm, 1-226 pulses, stable delivery except for shift change issues

Achievements/Observations

- PP laser alignment and optimization at IRU and PAM

- Aligned beam until IBS

- Checked MKB focus

- Timing at PAM

- First signals on GOTTHARD II

Issues

- Issues with shift change for PP laser. Intensity flucutation observed after shift change was done. This issue was similar to what was observed last year. We will inform LAS about this issue. No LAS OCD available to call before we leave after the shift (7:30 AM).

|

|

21

|

09 Feb 2023, 01:11 |

Jörg Hallmann | | Shift summary Feb 8th |

stable beam at 9kev (about 1.1 mJ)

checks of the sample environment required for the upcoming user experiment

test data aquisition of SiO2 samples (data analysis still ongoing)

commissioning of Jungfrau detectors & XTD6_ATT (closed loop operation)

test of operation with two different AGIPD triggers - normal one and an early one (leaving out the first 71 cells of AGIPD)

issues:

spectrometer motor XTAL_RX still not usable

first arm of XTD1_CRL is interlocked and cannot be used

|

|

20

|

08 Feb 2023, 11:14 |

Andreas Koch | XPD | SA3 status |

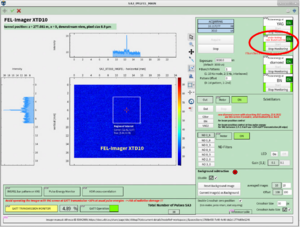

Bunch number control - SA3 FEL imager

As announced today in the XO meeting the SA3 FEL imager has a new feature, see screenshot, encircled:

- In case of danger for the YAG screen the bunches SA3 are set to "0" via the BunchPatternServer (SA3 Main scene).

What to do:

- Choose a different screen, BN or CBor, and again set the number of bunches needed.

- If operation with the YAG screen is wished reduce the pulse energy at the screen.

Further info:

- In general, danger to the YAG screen, even in single bunch operation, is avoided if the GATT is operated at <10% transmission. Observe the screen Watchdogs.

- This feature is installed at the SA3 FEL imager only, after new recent damages.

- Activate the device with "Start", deactivate the control with "Stop Monitoring".

In case of not-correct behaviour inform the PRC (Andreas Galler this week) or me.

This entry is copied to the ttfinfo logbook. |

| Attachment 1: Bunch_number_control_SA3_FEL_imager.PNG

|

|

|

19

|

29 Oct 2022, 11:03 |

Jaydeep Patel | | Jet alignment test- obeserver |

|

Nozzle type

|

Nozzle Aperture(µm)

|

Sample

|

Jet Speed(m/s)

|

He flow rate

|

Liquid flow rate

|

Repetition rate

|

Beam Attenuation

(%)

|

Run No.

|

|

GDVN

B

|

75

|

Water

|

25

|

10

|

80

|

0.5

|

9

|

122

|

|

30

|

13

|

60

|

0.5

|

9

|

123

|

|

40

|

20

|

30

|

0.5

|

23

|

124

|

|

45

|

25

|

30

|

0.5

|

23

|

125

|

|

50

|

32

|

30

|

0.5

|

23

|

126

|

|

Buffer 1

|

25

|

10

|

80

|

0.5

|

31

|

141

|

|

30

|

14

|

60

|

0.5

|

31

|

140

|

|

40

|

20

|

30

|

0.5

|

31

|

139

|

|

45

|

26

|

30

|

0.5

|

31

|

138

|

|

50

|

32

|

30

|

0.5

|

9

|

137

|

|

Buffer 2

|

25

|

|

|

|

|

|

|

30

|

|

|

|

|

|

|

40

|

|

|

|

|

|

|

45

|

|

|

|

|

|

|

50

|

|

|

|

|

|

|

Crystal size 1µm

|

25

|

10

|

80

|

0.5

|

16

|

131

|

|

30

|

13

|

60

|

0.5

|

16

|

130

|

|

40

|

20

|

30

|

0.5

|

16

|

129

|

|

45

|

25

|

30

|

0.5

|

16

|

128

|

|

50

|

32

|

30

|

0.5

|

16

|

127

|

|

Crystal size 2-4µm

|

25

|

10

|

80

|

0.5

|

12

|

132

|

|

30

|

13

|

60

|

0.5

|

9

|

133

|

|

40

|

20

|

30

|

0.5

|

9

|

134

|

|

45

|

25

|

30

|

0.5

|

9

|

135

|

|

50

|

32

|

30

|

0.5

|

9

|

136

|

|

Crystal size 5 µm

|

25

|

10

|

80

|

0.5

|

9

|

142

|

|

30

|

13

|

60

|

0.5

|

9

|

143

|

|

40

|

20

|

30

|

0.5

|

31

|

144

|

|

45

|

25

|

30

|

0.5

|

29

|

145

|

|

50

|

32

|

30

|

0.5

|

29

|

146

|

|

DFFN

JKMH8.11

8.11=75-70-70

|

75

|

water

|

25

|

13

|

80

|

0.5

|

|

|

|

30

|

13

|

40

|

0.5

|

|

|

|

40

|

20

|

20

|

0.5

|

|

|

|

45

|

25

|

15

|

0.5

|

|

|

|

50

|

32

|

15

|

0.5

|

|

|

|

Buffer1

|

25

|

|

|

|

|

|

|

30

|

|

|

|

|

|

|

40

|

|

|

|

|

|

|

45

|

|

|

|

|

|

|

50

|

|

|

|

|

|

|

Buffer2

|

25

|

|

|

|

|

|

|

30

|

|

|

|

|

|

|

40

|

|

|

|

|

|

|

45

|

|

|

|

|

|

|

50

|

|

|

|

|

|

|

Crystal size 1 µm

|

25

|

|

|

|

|

|

|

30

|

|

|

|

|

|

|

40

|

|

|

|

|

|

|

45

|

|

|

|

|

|

|

50

|

|

|

|

|

|

|

Crystal size 2-4 µm

|

25

|

|

|

|

|

|

|

30

|

|

|

|

|

|

|

40

|

|

|

|

|

|

|

45

|

|

|

|

|

|

|

50

|

|

|

|

|

|

|

Crystal size 5 µm

|

25

|

|

|

|

|

|

|

30

|

|

|

|

|

|

|

40

|

|

|

|

|

|

|

45

|

|

|

|

|

|

|

50

|

|

|

|

|

|

|

GDVN

C/C4

C=100-90-100

C4=100-75-100

|

100

|

Water

|

26

|

15

|

80

|

0.5

|

58%

|

172

|

|

30

|

20

|

60

|

0.5

|

58%

|

171

|

|

40

|

35

|

25

|

0.5

|

58%

|

170

|

|

45

|

37

|

25

|

0.5

|

58%

|

174

|

|

50

|

40

|

18

|

0.5

|

58%

|

175

|

|

Buffer 1

|

26

|

|

|

|

|

180

|

|

30

|

|

|

|

|

179

|

|

40

|

|

|

|

|

178

|

|

45

|

|

|

|

|

177

|

|

50

|

|

|

|

|

176

|

|

Buffer 2

|

25

|

|

|

|

|

|

|

30

|

|

|

|

|

|

|

40

|

|

|

|

|

|

|

45

|

|

|

|

|

|

|

50

|

|

|

|

|

|

|

Crystal size 1 µm

|

25

|

|

|

|

31%

|

181

|

|

30

|

|

|

|

31%

|

182

|

|

40

|

|

|

|

31%

|

183

|

|

45

|

|

|

|

31%

|

184

|

|

50

|

|

|

|

31%

|

185

|

|

Crystal size 2-4 µm

|

25

|

|

|

|

31%

|

187

|

|

30

|

|

|

|

31%

|

188

|

|

40

|

|

|

|

31%

|

189

|

|

45

|

X

|

X

|

X

|

X

|

X

|

|

50

|

X

|

X

|

X

|

X

|

X

|

|

Crystal size 5 µm

|

25

|

20

|

80

|

0.5

|

16/ 31%

|

147/190c4

|

|

30

|

30

|

60

|

0.5

|

31%

|

192

|

|

40

|

40

|

25

|

0.5

|

31%

|

193

|

|

45

|

40

|

15

|

0.5

|

|

|

|

50

|

40

|

10

|

0.5

|

|

|

|

|

18

|

05 Feb 2023, 12:32 |

Natalia, Zhong | SCS | morning shift summary |

achievements:

- Viking spectrometer set up in 8th order around 1280eV and calibrated

problems:

- problems with Viking motors. Took couple of hours to solve, Martin came on site

- problems with moving exit slit (Blade_Bottom motor does not move). Not solved by EEE on call, may be mechanical problems. Called run coordinator, XRO on call (Maurizio) is going to inspect the slit in the tunnel today. Operation of SCS relies on exit slit available (now it opened to ca. 10mm) |

|

17

|

05 Feb 2023, 15:18 |

Harald Sinn | PRC | Issue |

15:15 SCS called and reported an issue with one of the motors of the SCS exit slit. DOC already looked at the problem and could not make the motor move. XRO (Maurizio) is now informed and looks at the problem

17:10 ZZ access to XTD by Maurzio and Mikako

18:00 ZZ finished. Unfortunatly the motor is completely blocked, even with cables disconnected one cannot move it. |

|

16

|

05 Feb 2023, 08:40 |

karen appel | HED | Shift summary |

Start up of HED ongoing for the three shifts

Day shift:

- work on the new X-ray alignment scheme at 2, 2.5 and 3 mrad: test was positive and we can not work with Tx of M3 fixed at 4 mm for all M1 and M2 mirror angles.

- alignment of CRL2 to the new beam axis in XTD6

Late shift:

- test of MDL at 2 , 2.5 and 3 mrad: the beam was brought back with the actual stored positions

- Continuation of commissioning of the new IPM

- PAM, ILM and power slit alignment to new beam axis

- ALAS alignment to the new beam position

Night shift:

- AGIPD tests after ASICS have been replaced and timing scans, flat fielding could not be achieved and has to be done prior to the next user experiment in May using AGIPD

- Test of epix after repair (new Peltier)

Issues:

- calibration pipeline of epix does not work as darks cannot be applied and there is no signal on the background corrected signal

- there has been obviously some miscommunication about the RF window length: HED had requested 150 musec for the weekend and XO had confirmed that on Friday. To do that the timing was shifted earlier by 10 -20 musec on Friday. It sseems that this was no longer the setting for Saturday evening when we needed that for AGIPD test. Not sure where the message got lost.

|

|

15

|

04 Feb 2023, 08:34 |

karen appel | HED | Shift summary |

We took the beam from 7 am, 24 h operation in three shifts.

We set up a new scheme for aligning the beam to the HED branch, which gives one X-ray axis downstream of the tunnel even if we operate at different angles of M1 and M2 (i.e. 3 to 2 mrad). This relies on a fixed M3 Tx position and was tested for 2.5 mrad and 3 mrad during the shifts. CRL3 in the HED optics hutch was aligned to the new beam postion, alignment of CRL2 in the XTD6 tunnel is still ongoing.

We tested most X-ray devices in the HED optics hutch and the HED experimental hutch and found them in good shape.

We tested and commissioned first time with the beam a new intensity position monitor at HED that was installed in the winter maintenance period in the HED optics hutch (inhouse design).

There was an issue with the M2 mirror feedback and we asked DOC to help us with that today already as we need to have a stabilised beam for the night when we are planning to do AGIPD and epix flat fileding. Work on that is ongoing.

|

|

14

|

02 Feb 2023, 09:25 |

Peter Zalden | FXE | Shift summary |

FXE bring-up, summary of shifts 31.1. and 1.2.:

Beam delivery (11.5 GeV)

- 9.3 keV, 1.5 mJ (31.1.)

- 7.1 keV, 1.7 mJ (1.2.)

- Horizontal beam jitter 200 µm (RMS), a bit more than usual

Tunnel alignment

- Align X-ray trajectory according to "fixed source" protocol with fixed TX of M3 in XTD9

- References saved for two offset configurations

- Beam transport diagnostics data taken to estimate source of jitter

Instrument Alignment Performed

- After WMP, calibrate slits, lenses and attenuators to the beam trajectory

- Check CRL performance after swap to new batch

- Prepare beam focus for next user expt at 9.3 and 7.1 keV

- Re-aligned FXE mono1 after 1st xtal swap

Issues

- Camera FXE_XTD9_MONO-1 BEAMVIEW could not be instantiated: Solved by DOC (suggested restarting the KaraboGUI)

- Issue with heater control on FXE mono: When switching ON in LOCAL mode it will apply max power; need to be in REMOTE first to control power via karabo

- FXE_XTD9_MONO-1/MDL/PITCH could not be instantiated: Solved by DOC (default config was wrong)

- SA1 DAQ PBM: DA01 in unknown state: Solved by DOC (IP misconfig.)

|

|

13

|

02 Feb 2023, 06:37 |

Chan Kim | SPB | Issue |

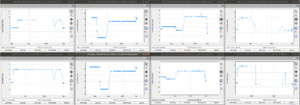

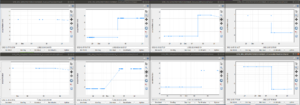

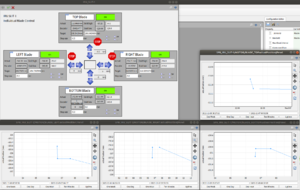

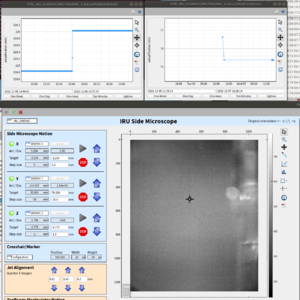

SPB_IRU_DPA/MOTOR issue

X stage looks okay, but Y, AX, and AY values have been changed by 2-3mm. (see attachment 1 and 2)

SPB_IRU_SLIT-1/MOTOR issue

All 4 blades (top, bottom, left, and right) have been changed by 0.1-0.5mm. (see attachment 3)

SPB_IRU_SIDEMIC/MOTOR and SPB_IRU_INLINEMIC/MOTOR issue

Not fully checked, but Y & Z motors of SideMic and AX & AY motors of InlineMic have been changed by ~1mm and ~0.4 karabo unit. (see attachment 4 and 5) |

| Attachment 1: Screenshot_from_2023-02-02_06-09-52.png

|

|

| Attachment 2: Screenshot_from_2023-02-02_06-11-30.png

|

|

| Attachment 3: Screenshot_from_2023-02-02_06-17-24.png

|

|

| Attachment 4: Screenshot_from_2023-02-02_06-30-00.png

|

|

| Attachment 5: Screenshot_from_2023-02-02_06-31-44.png

|

|

|

12

|

30 Jan 2023, 15:21 |

Maurizio Vannoni | XRO | SASE3 Summary of Maintenance Period and Ramp up activities |

SASE3 Summary of Maintenance Period and Ramp up activities

Maintenance

- Soft Mono motions (grating horizontal and grating pitch) were cleaned and lubricated

- Vertical slit encoders were double checked (without moving them) to exclude that Karabo errors are coming from them.

- Motors of Mirrors were inspected (without dismounting) to check if some strange noise is created during motion. The SA3 M2 Tx motor was very noisy at 0.035 speed and not anymore at 0.03.

- Settings of acceleration and velocity was optimised together with EEE (Bernard). The noise at SA3 M2 Tx was disappearing even with 0.035 speed.

- M1 and M2 chillers had service (water filling) and were then set on again before closing the tunnel. For M5 and M6, cooling is off.

- Piezo controller for M1 was disconnected and removed. Therefore, the M1 piezos are unavailable at the moment. This was agreed with the experiments after it was found some instabilities in the beam position (beam was moving by itself sometime).

- PBLMs were checked: https://in.xfel.eu/elog/XRO+Beam+Commissioning/76

Inst Dept Ramp up

- SA3 M2 RY was not moving. This took several hours to be solved. Temprary explanation: stepcounter value changed without any physical movement of the motor and later on, encoder was thought to be wrongly calibrated and thus adjusted. As a result, the motor position is lost and needs to be fiducialised again in the alignment.

- The performance of "Closed loop" and "Backlash Correction" was tested. The result is that the TY motors need to remain in open loop and with 'Backlash Correction' activated (value 2 microns). This is increasing the reproducibility of the positioning. The other motors could be used in closed loop if required, but then the Backlash Correction has to be deactivated.

- SA3 M6 RY encoder has an incorrect calibration at the moment. Please refer to the motor position only. We will work on a solution asap.

- The vertical slits (SCS, SQS, SXP) were checked and they move correctly.

- Several positions were fiducialised, that could be used as a starting point for Instruments fine alignment:

SXP 9mrad (8.9mrad) mono he premirror 937eV

SXP 9mrad (8.9mrad) unfocused

SCS 9mrad (8.9 mrad) unfocused

SCS 9 mrad (8.3mrad) unfocused

SQS 9mrad (8.7mrad) unfocused

SQS 20mrad (18.5mrad) unfocused

- SEPS interlock was succefully tested: https://in.xfel.eu/elog/XRO+Beam+Commissioning/112

|

|

11

|

30 Jan 2023, 19:06 |

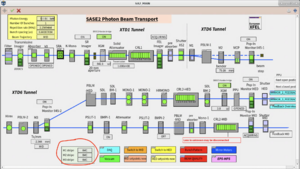

Maurizio Vannoni | XRO | SASE2 Summary of Maintenance Period and Ramp up activities |

SASE2 Summary of Maintenance Period and Ramp up activities

Maintenance

- Many vibration tests were done.

- M1 chiller had service (water filling) and was then set on again before closing the tunnel. M2, M3 cooling is off.

Inst Dept Ramp up

- Positions reached:

MID 2.2 mrad at 9 keV

HED - 9keV - 2.7mrad - B4C stripe

- checks for the stripes were done:

M3 verification of coating positions and horizontality or the mirror

MID alignment Pt stripe - vertical motion of mirrors with Euler

- for the stripes, we have now a watchdog telling if the mirrors are on the B4C or the Pt stripe (see image below)

|

| Attachment 1: Screenshot_2023-01-30_at_19.27.42.png

|

|

|

10

|

30 Jan 2023, 16:31 |

Maurizio Vannoni | XRO | SASE1 Summary of Maintenance Period and Ramp up activities |

SASE1 Summary of Maintenance Period and Ramp up activities

Maintenance

- MC2 library update was deployed by EEE and most of the motors were tested afterwards

- Some motors were acting strangely: https://in.xfel.eu/elog/XRO+Beam+Commissioning/82

- As a rule, the Closed Loop and the Backlash Correction are atm incompatible and therefore you have to choose one of them. When a strong reproducibility is needed, the motor should remain in Open Loop and with Backlash Correction activated (2 microns for TY and 50 microns for TX, tipically): https://in.xfel.eu/elog/XRO+Beam+Commissioning/83|

- FXE mono1 bottom crystal was exchanged, realigned parallel to the beam. Recommissioning due WK5 together with FXE

- M1 and M2 chillers had service (water filling) and were then set on again before closing the tunnel. M3 is currently with cooling off.

Inst Dept Ramp up

- Several positions were fiducialised:

SPB alignment 2.41mrad 9keV

FXE alignment 2.4 mrad 9 keV |