| ID |

Date |

Author |

Group |

Subject |

|

184

|

29 Sep 2024, 00:07 |

Chan Kim | SPB | Shift summary |

**X-ray delivery**

- 6 keV, ~2.8 mJ, stable delivery

**Optical laser delivery**

- ns laser for particle visualization

**Achievements/Observations**

- measured user sample for almost whole day (about 100 runs x 5 minutes)

- Julabo chiller (AGIPD) is still on target (-32 degree)

**Issues**

- MKB Ion pump error (issue fixed after resetting the device)

- NKB focus loosed. Focus reoptimized twice during the d2 shift |

|

183

|

28 Sep 2024, 23:42 |

Jörg Hallmann | MID | Shift summary |

continued with the evaluation of the XPCS analysis packages

investigated the effect of alignment optimizations and forced misalignments on the contrast directly with the online XPCS tool

checked additional standard samples

|

|

182

|

28 Sep 2024, 01:31 |

Jörg Hallmann | MID | Shift summary |

started with data acquisition for the ptycho experiment with different geometries

started with XPCS measurements of capillaries using the FSSS

issues: beam size changed a bit compared to yesterday (a bit bigger now - most proberly due to the realignment of the mirror suppressing the higher harmonics in the beam)

|

|

181

|

27 Sep 2024, 23:13 |

Chan Kim | SPB | Shift summary |

X-ray delivery

- 6 keV, ~3.0 mJ, stable delivery

Optical laser delivery

- ns laser for particle visualization

Achievements/Observations

- measured 1 sample roughly for 9 hours (hit rate went down in the afternoon)

- Julabo chiller (AGIPD) is still on target (-32 degree)

Issues

- NKB mirror drifted in vertical direction: it was optimized again at around 9pm

- extremely low hit rate even with sucrose (extremely few particles were observed in sidemic, 1 particle within a few seconds): maybe the aerodynamic lens should be cleaned

|

|

180

|

27 Sep 2024, 15:17 |

Jan Gruenert | PRC | Status |

Bunch pattern SA1 / SA3

SQS requests to change the bunch pattern.

Currently SA1/SA3 run interleaved as 131313...

The first bunch in the train (for SA1, non-lasing in SA3) nevertheless is visible as a small pre-peak in the diode signal which SQS uses to check the timing.

Therefore SQS requests to change to 31313131....

It was checked with SA1 (SPB/SFX) and the accelerator experts that this should not cause any issues (AGIPD detector is running on dynamic trigger),

therefore it was agreed that SPB/SFX informs BKR when there is a good moment without data acquisition, and BKR will make this change after informing SQS.

This change will happen within the next hour (as of 15h20). |

|

179

|

27 Sep 2024, 01:51 |

Jörg Hallmann | MID | Shift summary |

started initial alignment for the ptycho experiment

Continued with XPCS measurement using the levitation device

issues: contribution of the 2nd harmonic of 8 keV at 16 keV visible on the Jungfrau detector - surpressing via mirror alignment not successful |

|

178

|

26 Sep 2024, 23:12 |

Chan Kim | SPB | Shift summary |

X-ray delivery

- 6 keV, ~2.7 mJ, stable delivery

Optical laser delivery

- ns laser for particle visualization

Achievements/Observations

- NKB focus optimized

- ns laser aligned with particle beam

- particle injector position optimized

- measured 3 samples: roughly 2 hours per each sample

- one sample was measured with and without He gas

- Julabo chiller (AGIPD) is still on target (-32 degree)

Issues

- Beam drift in vertical direction: Rz has to be corrected during the measurement and moved by 0.2 mm in total in whole day (~18 hours)

|

|

177

|

26 Sep 2024, 01:46 |

Jörg Hallmann | MID | Shift summary |

Started the day with vacuum & detector issues

real start of the experiments only at about 6 p.m.

measurement of a selection of samples (urea, ludox) using the levitation device

issues: vacuum (behind AGIPD), motor (bend2 of the DES was in error - used for the beamstop) |

|

176

|

25 Sep 2024, 23:36 |

Chan Kim | SPB | Shift summary |

X-ray delivery

- 6 keV, ~2.8 mJ, stable delivery

Optical laser delivery

- ns laser for particle visualization

Achievements/Observations

- NKB focus optimized

- particle injection tested with gold nanoparticles

- ns laser roughly aligned with particle beam

- Julabo chiller (AGIPD) is still on target (-32 degree)

Issues

- XTD2_ATT Arm4 (600um thick CVD) is damaged (most probably last week)

|

|

175

|

25 Sep 2024, 16:53 |

Chan Kim | SPB | Issue |

600um thick CVD diamond (XTD2 attenuator) seems damaged

Attachment 1: 600um thick CVD diamond (Arm 4) OUT

Attachment 2: 600um thick CVD diamond (Arm 4) IN |

| Attachment 1: Screenshot_from_2024-09-25_16-50-57.png

|

|

| Attachment 2: Screenshot_from_2024-09-25_16-51-21.png

|

|

|

174

|

25 Sep 2024, 10:12 |

Raúl Villanueva-Guerrero | other | Issue |

Issue with SA3 Gas attenuator (SA3_XTD10_GATT) - SOLVED

Dear all,

after the reported issue by SQS colleagues regarding the impossibility to inject Argon, and after a first remote evaluation, we (VAC) have entered XTD10 to assess the status and verify the most probable working hypothesis: a manual valve in the supply line was closed (otherwise as expected). Joshua and Benoit confirmed it and the showstopper is now gone. The system is back to normal and standard operation can be resumed in any moment.

A small remark: as Argon (or any other gas different from Nitrogen) is not the default operation mode, it is important that if needed, there should be an explicit request during the preparation of the operation tables with XO. This would help to avoid this kind of situations. Unfortunately sending a short notice e-mail just before the next run is clearly not recommended.

With best regards. |

|

173

|

25 Sep 2024, 09:47 |

Jan Gruenert | PRC | Issue |

Issue with SA3 Gas attenuator (SA3_XTD10_GATT)

9h06: SQS informs PRC that the Argon line in GATT is not reacting on pressure change commands, no GATT operation, which is required to reduce pulse energies for alignment. VAC-OCD is informed.

ZZ access is required to check hardware in the tunnel XTD10.

SA1 / SPB is working on other problems in their hutch (water leaks) and don't take beam.

SA3 / SQS will work with the optical laser.

SA2 / MID will not be affected: there is also an issue in the hutch and MID currently doesn't take beam into the hutch, and would anyhow only very shortly be affected during the moment of decoupling the beamline branches.

9h45: BKR decouples North Branch (SA1/SA3) to enable ZZ accesss for the VAC colleagues.

ZZ access of VAC colleagues.

10h12: The problem is solved. A manual intervention in the tunnel was indeed necessary. VAC colleagues are leaving the tunnel.

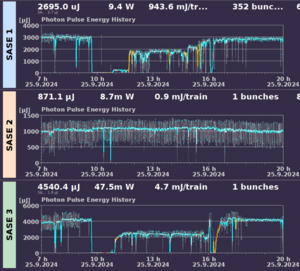

- Beam down SASE1: 9h43 until 10h45 (1 hour no beam), tuning done at 11h45, then 1.7mJ at 6keV single bunch.

- Beam down SASE3: 9h43 until 10h56 (1.25 hours no beam). Before intervention 4.2mJ average with 200 bunches, afterwards 2.5mJ at 400 eV / 3nm single bunch.

|

| Attachment 1: JG_2024-09-29_um_12.06.37.png

|

|

|

172

|

21 Sep 2024, 09:50 |

Peter Zalden | FXE | SA1 status |

The xray beam drifted significantly on wednesday and thursday (18. and 19.) but then was not drifting on friday (20.), see attached trendline of the M2 actuator that kept the beam at fixed position on M3.

Today also seems that beam pointing is stable. But unclear what happened earlier... |

| Attachment 1: 2024-09-21-094858_073864177_exflqr51474.png

|

|

|

171

|

16 Sep 2024, 02:21 |

Wonhyuk Jo | MID | Shift summary |

- Pump-probe experiments are being conducted using PuMa and PP laser.

- The user program is ongoing over the night.

Tomorrow,

- Rotating the sample phi angle. The sample holder will be retracted from the MPC.

- Search the asymmetric film peak and conduct the PuMa and PP laser experiment. |

|

170

|

15 Sep 2024, 23:12 |

Raphael de Wijn | SPB | Shift summary |

X-ray delivery

8.951 keV, 1.6 mJ up to 16 pulses at 113 kHz

Achievements/Observations

More than 1h of beam sweeping with lysozyme crystals

Several runs of vitamin C beam sweeping data

Issues:

Several synchronization methods were tested for the mirrors but without improving it

|

|

169

|

15 Sep 2024, 02:16 |

Wonhyuk Jo | MID | Shift summary |

- The seeding optimization is ongoing, which was not successful. Now we have a total of 170 uJ including SASE and seeding.

- The option to switch to SASE is relatively not complex and can be done with the support of BKR without a seeding expert. BKR expects to provide about (more than) 1 mJ. To be discussed with user later.

- An investigation of the asymmetric film peak is ongoing to optimize the measurement conditions, such as diffraction angle, sample temperature dependence, and pump laser effect. Still, the PP laser effect on the diffraction peak on the asymmetric peak is unclear. The higher sample temperature suppresses the diffraction intensity. Unclear intensity changes over time have been observed.

- The AGIPD moved closer to the sample to cover the more solid angle.

- The MDL of the coupled motion of the hexapod and puma manipulator is not working reliably.

- The delay time between the X-ray and the PP laser was cross-checked to ensure its correctness. No timing drift was confirmed.

- Laser pump and X-ray probe experiment is being conducted at the vicinity of subtract peak. After optimizing the spatial overlap by scanning, the pump laser effect was clearly achieved.

- The user program will be ongoing over the night.

|

|

168

|

14 Sep 2024, 23:13 |

Raphael de Wijn | SPB | Shift summary |

X-ray delivery

8.951 keV, 1.2 mJ up to 30pulses at 113 kHz

Achievements/Observations

Beam trajectory at 8.951 keV

IRDa slits left/right blades connected

Sweeped pulses could be observed on fluorescent paper in front of the Downstream screen

Mirror synchronisation parameters could be found

Jungfrau halves were closed and the downstream cone installed

Background was minimised using the IRDa slits |

|

167

|

14 Sep 2024, 02:23 |

Wonhyuk Jo | MID | Shift summary |

- The seeding optimization result: Total 450 uJ (Seeding of 150 uJ + SASE of 300 uJ). BKR will be able to start optimization on Saturday around noon if necessary.

- The pump-probe (PP laser and PuMa pulse) experiment data on the substrate peak was collected.

- Found the film peak on the AGIPD. Intensity optimization was not successful. We keep losing diffraction peak intensity over the measurement time and number of pulses. We assume the X-ray-induced heating can affect the diffraction intensity.

- Rotating Phi angle by moving the manipulator Z direction helped to bring the peak out of the detector gap.

|

|

166

|

14 Sep 2024, 01:33 |

Peter Zalden | FXE | Status |

FXE received the beam and did not change accelerator settings.

Beam alignment to FXE was re-established using the new values for the old M1/M2 offset.

Monochromator aligned to the SPB energy setpoint.

THz source aligned to Xrays and several reference positions for Xray pointing taken. Further steps require THz radiation, which is not available at this point.

Xrays realigned back to SPB XTD9 screen. |

|

165

|

13 Sep 2024, 23:17 |

Adam Round | SPB | Shift end |

On Shift: TS, FT, CK, AR, PS

X-ray delivery

8.951 keV, 1.6 mJ up to 200 pulses at 0.5 MHz (intesity drops off at end of train)

Achievements/Observations

Beam trajectory and focusing re-established at 8.951 keV

Temporary beamstop verified position for sweeping - confirmed by eric

Beam sweeping in synchronisation with pulse trains observed!

slit window assembly remounted and beam is going through to back of hutch in perparation for optimisation next shft |